Your garden cleaning tools can make or break your plants’ health. But here’s what most gardeners don’t realize: those dirty, dull pruning shears you’ve been using might be harming your precious plants more than helping them.

Think about it. Every cut you make with dirty blades spreads disease from one plant to another. Dull edges crush stems instead of making clean cuts. And that expensive pair of plant clippers you bought last season? They’ll need replacing much sooner if you don’t maintain them properly.

This guide shows you exactly how to clean shears and keep them razor-sharp. You’ll learn the step-by-step process to maintain your gardening tools, protect your plants from disease, and save money by extending your tools’ lifespan. Whether you’re dealing with basic maintenance or tackling stubborn rust, we’ve got you covered.

Оглавление

ПереключатьWhy Clean Garden Shears Matter for Your Garden’s Health

The Hidden Dangers of Dirty Pruning Shears

Dirty pruning shears act like tiny disease carriers in your garden. Each time you cut an infected plant and move to a healthy one, you’re potentially spreading bacterial infections, fungal diseases, and viruses. Fire blight, bacterial canker, and powdery mildew can all hitch rides on your blade edges.

But disease transmission isn’t the only problem. Dirty blades become dull faster because sap and debris build up on the cutting edges. This buildup forces you to apply more pressure when cutting, which can damage both your plants and your hands. The extra force also puts unnecessary stress on the tool’s moving parts.

Your plant trimmers weren’t designed to push through sticky residue and rust. When they’re forced to work harder, springs wear out faster, pivot points loosen, and blade alignment shifts. This cascading effect turns a simple maintenance issue into an expensive replacement problem.

Benefits of Regular Garden Cleaning Tools Maintenance

Clean garden shears create precise, surgical cuts that heal quickly and resist infection. Plants respond better to clean cuts because the wound closes faster, and disease organisms have less opportunity to enter. Your roses, fruit trees, and shrubs will thank you with healthier growth and better flowering.

Performance improves dramatically with regular maintenance. Sharp, clean blades glide through branches with minimal effort. You’ll notice reduced hand fatigue during long pruning sessions. And those tough, woody stems that used to require multiple cuts? They’ll slice cleanly in one smooth motion.

Tool longevity increases significantly when you maintain your equipment properly. Professional landscapers often use the same high-quality sharpening garden pruners for decades with proper care. Regular cleaning prevents rust formation, lubrication keeps moving parts smooth, and proper storage protects against environmental damage.

When and How Often to Clean Pruning Shears

Daily Cleaning Schedule

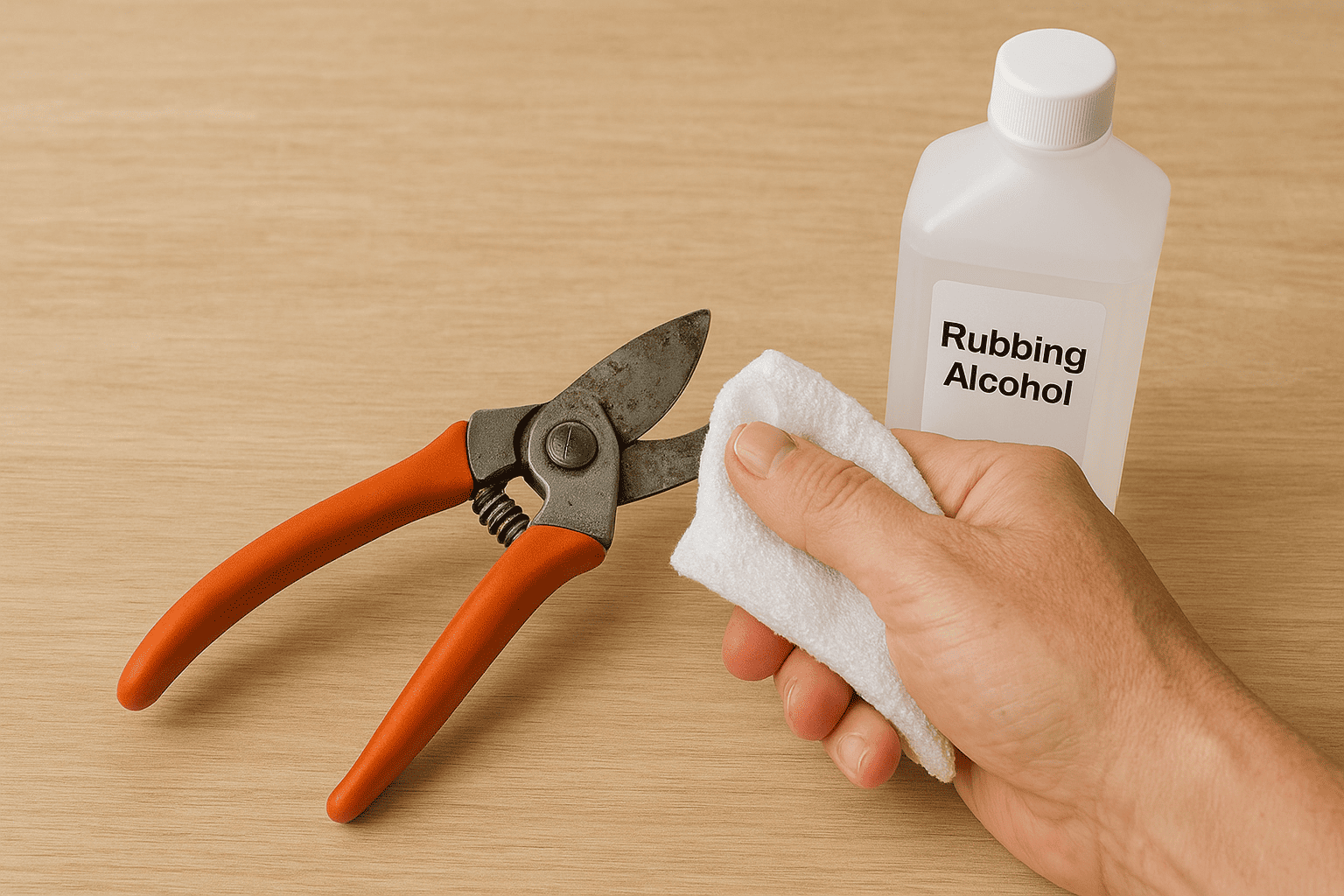

Disease prevention requires immediate action when working with infected plants. How to disinfect pruning shears becomes critical when moving between diseased and healthy specimens. Wipe blades with rubbing alcohol between each plant when dealing with bacterial or fungal infections.

End-of-day maintenance takes just five minutes but prevents major problems. Rinse off sap and debris with water, dry thoroughly, and apply a light coat of oil to prevent overnight rust formation. This simple routine keeps your garden cleaning tools ready for tomorrow’s work.

But don’t stop at basic cleaning. Check blade alignment, test the cutting action, and look for early signs of wear or damage. Catching small problems early prevents them from becoming major repairs later.

Deep Cleaning Schedule

Annual deep cleaning should happen at least once per year, preferably in spring before heavy growing season use. This comprehensive maintenance includes complete disassembly, thorough rust removal, sharpening, lubrication, and reassembly. Many gardeners combine this with their seasonal garden cleaning routine.

Fall cleaning before winter storage deserves special attention. Remove all organic material that could harbor moisture and cause rust. Apply protective oil coatings and store in dry conditions. Your tools will emerge from winter storage ready for immediate use.

Watch for warning signs that indicate immediate attention is needed. Sticky blades, difficult cutting action, visible rust spots, or loose pivot points all signal that your pruning shears sharpening schedule needs acceleration.

Essential Supplies for Cleaning Garden Shears

Basic Cleaning Supplies

Warm, soapy water remains the foundation of cleaning garden shears. Use dish soap and a stiff brush to remove most dirt, sap, and organic debris. The soap breaks down sticky residues while the brush provides mechanical scrubbing action without scratching metal surfaces.

Steel wool and scrubbing pads handle stubborn buildup and light rust. Choose fine-grade steel wool for delicate surfaces and coarser grades for heavy rust removal. However, be cautious around moving parts, as metal particles could cause damage.

Clean microfiber cloths work best for drying and final polishing. They absorb moisture effectively without leaving lint behind. Keep several on hand because you’ll need fresh, dry clothes for the final steps.

Disinfecting Solutions

Seventy percent isopropyl alcohol provides the most efficient disinfection for sanitizing pruning shears. It evaporates quickly, kills most plant pathogens, and doesn’t require rinsing. Simply wipe the blades with an alcohol-soaked cloth, and you’re ready to continue working.

Bleach solutions offer thorough disinfection for serious disease problems. Mix one part bleach with nine parts water for effective pathogen control. But bleach requires contact time to work correctly and must be rinsed off to prevent metal corrosion.

Hydrogen peroxide works well for soaking heavily contaminated tools. It breaks down organic matter while providing antimicrobial action. Commercial garden disinfectants are convenient but often contain similar active ingredients at higher concentrations.

Step-by-Step Guide: How to Clean Shears Properly

Basic Cleaning Process

Safety gear protects you during the cleaning and pruning shears process. Wear gloves to protect your hands from sharp edges and cleaning chemicals. Safety glasses prevent splashing solutions from reaching your eyes. These simple precautions prevent the majority of cleaning-related injuries.

Start with a thorough rinse using your garden hose. This removes loose dirt, leaves, and debris that could scratch surfaces during the scrubbing process. Pay special attention to the pivot area where organic matter tends to accumulate.

Scrub away built-up sap and dirt using warm, soapy water and a stiff brush. Work the cleaning solution into all crevices and moving parts. For stubborn sap deposits, commercial cleaners like Scrubbing Bubbles effectively break down sticky residues.

Rinse thoroughly with clean water to remove all soap residue. Soap left on metal surfaces can attract dirt and moisture. Follow up with complete drying using clean towels or compressed air to prevent rust formation.

How to Disinfect Pruning Shears

Choose your disinfection method based on the situation. Rubbing alcohol works quickly for routine disinfection between plants. Bleach solutions provide deeper antimicrobial action for serious disease outbreaks. Hydrogen peroxide offers middle-ground effectiveness with less corrosion risk.

The application method affects disinfection effectiveness. Wiping with alcohol-soaked cloths works for quick disinfection. Soaking in bleach solution ensures complete coverage but requires more time. Spray bottles provide even coverage for large tool surfaces.

In garden settings, a freshly prepared 10 % bleach solution (1 part household bleach to 9 parts water) should be used within two hours of mixing and tools should be soaked for 30 minutes to ensure complete disinfection of pruning equipment and eliminate plant pathogens Don’t rush this step insufficient contact time can leave viable pathogens behind, undermining your sanitation efforts. Always follow the recommended dwell times and keep surfaces visibly wet for the full duration before rinsing or wiping.

Remove Rust from Garden Tools

Assessment determines the best way to clean garden tools affected by rust. Light surface rust responds to steel wool and elbow grease. Heavy rust may require chemical treatment or professional restoration. Deep pitting might mean replacement time has arrived.

White vinegar provides safe, effective rust removal through overnight soaking. The acetic acid dissolves rust while being gentle on the underlying metal. This method works well for tools with light to moderate rust problems.

WD-40 penetrates heavy rust and loosens stubborn deposits. Apply liberally and allow ten minutes for penetration before scrubbing with steel wool. This combination handles rust that vinegar alone cannot dissolve.

When to Take Apart Your Shears

End-of-season maintenance justifies complete disassembly for thorough cleaning and inspection. This deep maintenance reveals hidden problems and allows access to normally unreachable areas. Take photos before disassembly to ensure proper reassembly.

Heavy rust or mechanical problems require disassembly for proper assessment and repair. Sometimes damage that appears minor from the outside reveals significant internal issues. Documentation helps track component condition over time.

Disassembly Process

Photography documents each step of disassembly for accurate reassembly. Take multiple angles showing how components fit together. These reference photos prevent confusion during reassembly weeks or months later.

Component removal typically involves unscrewing the nut that holds the blade assemblies together. Work slowly and keep track of washers, springs, and spacers. Some tools use specialized fasteners that require specific tools or techniques.

Organization prevents lost parts and speeds reassembly. Lay components in order on a strip of duct tape to maintain sequence. Label small parts if necessary. Clean components individually in soapy water for thorough maintenance.

How to Sharpen Pruners: Complete Sharpening Guide

Signs Your Pruning Shears Need Sharpening

Cutting performance degrades gradually, making it easy to miss the signs that sharpening pruning shears has become necessary. Pay attention to the amount of pressure required for cuts. Sharp blades slice through branches with minimal force while dull blades require significant pressure.

Cut quality provides clear indicators of blade sharpness. Sharp plant clippers create clean cuts that heal quickly. Dull blades crush stems, creating ragged wounds that invite disease and pest problems. If your cuts look more like damage than precise surgery, it’s time to sharpen.

Essential Sharpening Garden Pruner Tools

Diamond files offer superior cutting ability and longevity compared to traditional steel files. They’re available in coarse, fine, and extra-fine grits for progressive sharpening. The coarse grit removes nicks and reshapes damaged edges while fine grits polish cutting surfaces.

Whetstones provide traditional sharpening methods that many professionals prefer. Soak stones in water before use to prevent loading with metal particles. The water also provides lubrication that reduces friction and heat buildup during sharpening.

Carbide sharpening tools offer quick touch-ups for maintaining sharp edges between major sharpening sessions. They’re beneficial for field maintenance when full sharpening isn’t practical.

Step-by-Step Sharpening Pruning Shears Process

Подготовка

Clean garden shears thoroughly before sharpening to prevent debris from interfering with the process. Sap and dirt on blade surfaces prevent files from cutting properly and can cause uneven sharpening results.

Safety equipment protects you during the sharpening hand pruners process. Gloves prevent cuts from sharp metal filings while safety glasses protect against flying particles. Secure the tool in a vise or clamp system for safe, controlled sharpening.

Sharpening Technique

Identify the factory bevel angle, typically around 22.5 degrees for most pruning shears. This original angle provides the best cutting performance and should be maintained during sharpening. Changing the angle can reduce cutting effectiveness.

File direction matters significantly for effective sharpening. Always work from the inside of the blade toward the outside edge. This direction maintains the proper cutting geometry and prevents the creation of a wire edge that reduces sharpness.

Progressive grits create the sharpest possible edge. Start with coarse files to remove nicks and reshape damaged areas. Move to fine grits for polishing and finishing. Each grit removes scratches left by the previous one.

Burr removal completes the sharpening process. The filing action creates tiny metal curls on the back edge of the blade. Remove these burrs with a fine file or sharpening stone, working gently on the flat back surface.

Testing Sharpness

Paper cutting tests provide immediate feedback on sharpening effectiveness. Sharp blades slice cleanly through paper without tearing or requiring sawing motions. If the blade catches or tears the paper, additional sharpening is needed.

Real-world testing on small branches confirms cutting performance. Sharp plant trimmers should slice through green wood with minimal pressure and leave clean, precise cuts.

Sharpening Hand Pruners vs. Other Garden Tools

Bypass pruning shears require different techniques than anvil-style tools. Only sharpen the cutting blade on bypass pruners – the anvil plate should remain flat. Sharpening both surfaces changes the cutting geometry and reduces performance.

Loppers and hedge shears use similar techniques but may require different angles or approaches based on their design. Heavy-duty tools often use steeper blade angles for increased durability at the expense of some cutting finesse.

Proper Lubrication and Final Assembly

Best Oils for Garden Tools

WD-40 and 3-in-1 oil work well for moving parts and pivot points. These penetrating oils displace moisture while providing ongoing lubrication protection. Apply sparingly to prevent dirt attraction and messy buildup.

Camellia oil offers superior rust prevention with excellent lubrication properties. This traditional tool oil penetrates deeply and provides long-lasting protection without attracting dirt. It’s perfect for tools stored in humid conditions.

Boiled linseed oil works well for wooden handles and offers some protection against metal. But avoid petroleum-based products if the tools will contact soil, as they can harm beneficial soil organisms.

Reassembly and Testing

Apply lubricant to all moving parts before reassembly. A few drops on pivot points and spring mechanisms ensure smooth operation and prevent premature wear. Wipe away excess to prevent dirt accumulation.

Reassemble carefully using your reference photos to ensure proper component positioning. Tighten fasteners firmly, but avoid over-tightening, as this can damage threads or restrict movement.

Function testing confirms proper reassembly and adjustment. Check that blades align properly, springs return components to position, and the cutting action feels smooth and controlled.

Seasonal Garden Cleaning and Maintenance Schedule

| Season Schedule | Tasks |

| Spring Preparation | • Annual tool inspection and disinfection • Sharpening before heavy growing season • Handle maintenance and replacement |

| Growing Season Maintenance | • Weekly tool stock and cleaning (for professionals) • Sharpening every 6 weeks (for heavy users) • Disease‑prevention protocols |

| Fall Storage Preparation | • Thorough cleaning before winter storage • Complete rust removal and oil treatment • Handle sanding and conditioning |

Proper Storage for Garden Cleaning Tools

Optimal Storage Conditions

Dry, well-ventilated storage areas prevent the moisture buildup that leads to rust and deterioration. Avoid damp basements, unheated garages with condensation problems, and outdoor storage that exposes tools to weather extremes.

Hanging storage keeps cutting edges protected and prevents damage from contact with other tools. Wall-mounted racks and pegboard systems organize tools while maintaining easy access for daily use.

Small tools benefit from specialized storage solutions. Sand-filled buckets provide protective storage that also helps maintain sharp edges through light abrasive action during insertion and removal.

Organization Systems

Tool racks and pegboard systems create organized storage that speeds tool selection and encourages proper maintenance habits. When tools have designated places, missing or damaged items become obvious immediately.

Individual storage spaces prevent tools from damaging each other during storage. Blade guards, sheaths, and separate compartments protect cutting edges and prevent accidents during tool retrieval.

Labeling and inventory systems help track tool condition and maintenance schedules. Simple tags noting last sharpening date or maintenance needs help ensure nothing gets overlooked.

Troubleshooting Common Problems

Persistent Rust Issues

Advanced rust removal techniques become necessary when standard methods fail. Electrolytic rust removal, naval jelly, and professional restoration services can save severely damaged tools that would otherwise require replacement.

Replacement versus restoration decisions depend on tool quality, replacement costs, and sentimental value. High-quality tools often justify extensive restoration, while cheap tools may be more economical to replace.

Prevention strategies focus on moisture control, protective coatings, and proper storage. Regular inspection and immediate treatment of early rust formation prevent minor problems from becoming major restoration projects.

Sharpening Challenges

Nicked and damaged blades require careful assessment before sharpening attempts. Minor nicks can be removed through progressive filing, while major damage may require professional grinding or blade replacement.

Angle maintenance becomes challenging on heavily worn tools where original bevels have been lost. Use angle guides or professional services to reestablish proper cutting geometry.

Professional sharpening services handle problems beyond typical homeowner capabilities. Complex blade repairs, precision angle restoration, and specialized tool maintenance often require professional equipment and expertise.

Mechanical Problems

Blade gap adjustments affect cutting performance and tool safety. Proper gap settings ensure clean cuts while preventing blade binding or excessive looseness that reduces cutting control.

Spring replacement addresses tools that no longer return to their proper position after cutting. Worn springs affect cutting action and can lead to user fatigue and poor cutting results.

Handle repair options range from simple grip replacement to complete handle rebuilding. Cracked or damaged handles create safety hazards and should be addressed immediately.

Заключение

Regular maintenance of your pruning shears transforms them from simple tools into precision instruments that protect your garden’s health. The time invested in cleaning garden shears and keeping them sharp pays dividends through better plant health, reduced disease transmission, and extended tool life.

Clean pruning shears create the precise cuts that help plants heal quickly and resist infection. Sharp blades reduce your workload while improving results. And proper maintenance extends tool life significantly, making quality tools a smart long-term investment.

Start implementing these maintenance routines today. Your plants will respond with healthier growth, and your tools will serve you reliably for many seasons. The difference between well-maintained and neglected garden инструменты для чистки becomes obvious once you experience the superior performance that proper care provides.